Frequently Asked Questions

Does RTA need a boiler inspection to quote RTA chemical accurately?

In most cases, we do not need a boiler inspection. Our office contact service people have seen 1000’s of boiler and boilers rooms. We can typically respond appropriately with your verbal description. If you provide pictures of your equipment, that can help even more. We are glad to help you with service at a distance.

Nonetheless, we are happy to visit you at your place of business, see the boiler room, and discuss the characteristics of your systems.

We are also happy to give you a FREE CHEMICAL TEST with our evaluation of what can be done to improve. CALL US FOR AN APPOINTMENT!

See On site services.

If you are opening your boiler soon, we would be happy to see inside. Just let us know when that inspection will occur.

What acid cleaning solution?

RTA has safely and effectively chemically cleaned thousands of boilers and other types of equipment. RTA frequently uses a cleaning solution that has an acid base See Boiler Acid Cleaning procedure. So first we determine the individual identity of all materials in the system. Based upon this information RTA chooses the proper cleaning solution, since that cleaning solution will be in contact with those materials. RTA follows Local codes and regulations in the choice and disposal of the cleaning solution. See acid cleaning questions to specify materials in a system that you propose to clean.

Note- RTA typically does not sell acid-based chemicals for direct unsupervised customer cleaning. We require that our people supervise the cleaning to be able to most effectively follow safe and proper procedures. We also provide any licenses and insurance required for the cleaning.

The Boiler Acid Rinse is an alternative to a complete 95% clean guaranteed acid cleaning. This approach normally includes limited use of acid. So it is potentially less aggressive to the boiler.

A piece of scale is loosely attached to the tube in the picture below. Such loose pieces are sent to drain during the rinsing of the boiler. Also, note the black magnetic iron oxide on the tube sheet. This is a corrosion product of previous attack of oxygen on the steel of the boiler. It is frequently not desirable to try to clean this corrosion product.

Can you ship chemical the same day?

We can ship chemical the same day to you, right after the order is placed. We typically ship the same day or next day after your order is placed if you need it quickly. If we deliver using our company trucks you will receive it that day. See delivery to point of use.

Are water softeners necessary?

Small and low pressure steam boilers, hot water boilers

Water softeners are not always necessary for smaller and low pressure steam boilers with low makeup water use to the system. But a water softener will take out the calcium and magnesium which are typically the largest ingredients in scale. So they are always beneficial. Nonetheless, by applying the correct chemical the boiler can remain clean even without a water softener.

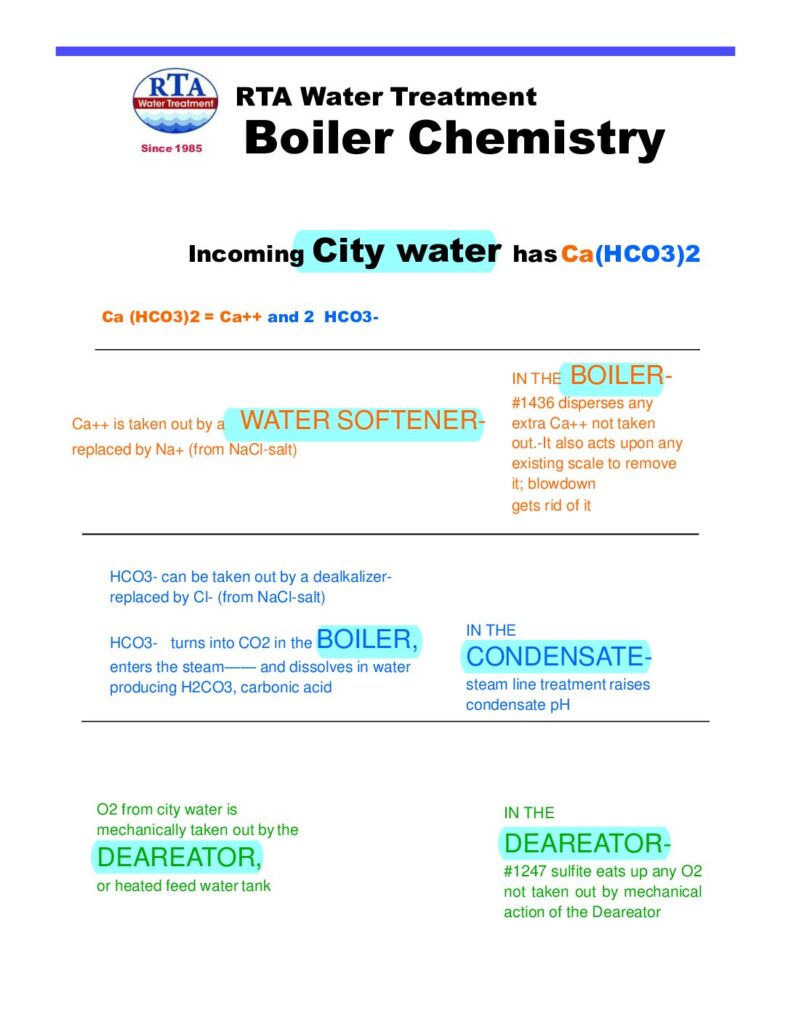

Additionally, with limited makeup to the system, less potential for deposit occurs. So for hot water boilers, with essentially very little or no makeup, softening of the make up is not necessary. Contact us for specific applications. See the “Boiler Chemistry” below Diagram. Note the effect of unsoftened water.

Large makeup and high pressure steam boilers

For larger makeup steam boilers, especially with higher pressures, softeners are necessary for the removal of calcium, magnesium, and other minerals. So they are especially critical in keeping boilers free from deposit. It is necessary to keep even very small amounts of calcium (and magnesium) hardness from getting into the boiler system to prevent deposits from occurring.

The diagram below shows why water softeners are necessary

1. Hard water enters from a city or well source,

2. The hard water is then softened, taking out the calcium and magnesium components of the hard water, together with some iron and other minerals.

3. Following the softeners, some systems include a dealkalizer. The dealkalizer takes out the HCO3- component in the water. Otherwise, when water is heated in the boiler, the HCO3- will produce CO2 (carbon dioxide). This carbon dioxide dissolves in the system condensate, producing corrosive low pH water, causing low pH corrosion.

Systems not having dealkalizers use steam line treatment to raise the pH in the condensate return lines so that corrosion does not occur. Limited amounts of steamline treatment (10% or so) are typically used even when a dealkalizer is present.

4. Deareators or heated feedwater tanks frequently replace an unheated feedwater tank. These eliminate O2 to a greater or lesser extent, depending on the type.

Is service day or night provided?

We provide service day or night. The RTA main phone number is always available both day, night, and including weekends for receiving contact from customers. Also, an 800 number is also serviced by Infotrac for chemical spills and other emergencies on a 24 hour basis. Infotrac is an outside contracting company that provides chemical safety information backup service day or night. See Your Customer Assurance from RTA.

If no contact is made with a “live” person, leave a message, text 269-317-8122, or email us at rtawtertreatment@gmail.com. If there is an urgency, let us know in the message. Otherwise, we will be sure to get back with you within 24 hours. See Dual Testing.

Do You Supply Waste Treatment Chemicals?

RTA Water Treatment does supply waste treatment chemicals, as well as chemicals for application to boilers and cooling systems. Waste treatment chemicals are formulated individually for specific industrial applications. Please contact us to visit your facility to evaluate the waste treatment need that you have. After testing your waste and applying choices of chemical, we will provide competitive pricing. To help us get started, please specify what type of waste you are treating. Contact us

???????? ENTER QUESTION BELOW ????????

To add to our Frequently Asked Questions List, fill out the form below