Are water softeners necessary?

Small and low pressure steam boilers, hot water boilers

Water softeners are not always necessary for smaller and low pressure steam boilers with low makeup water use to the system. But a water softener will take out the calcium and magnesium which are typically the largest ingredients in scale. So they are always beneficial. Nonetheless, by applying the correct chemical the boiler can remain clean even without a water softener.

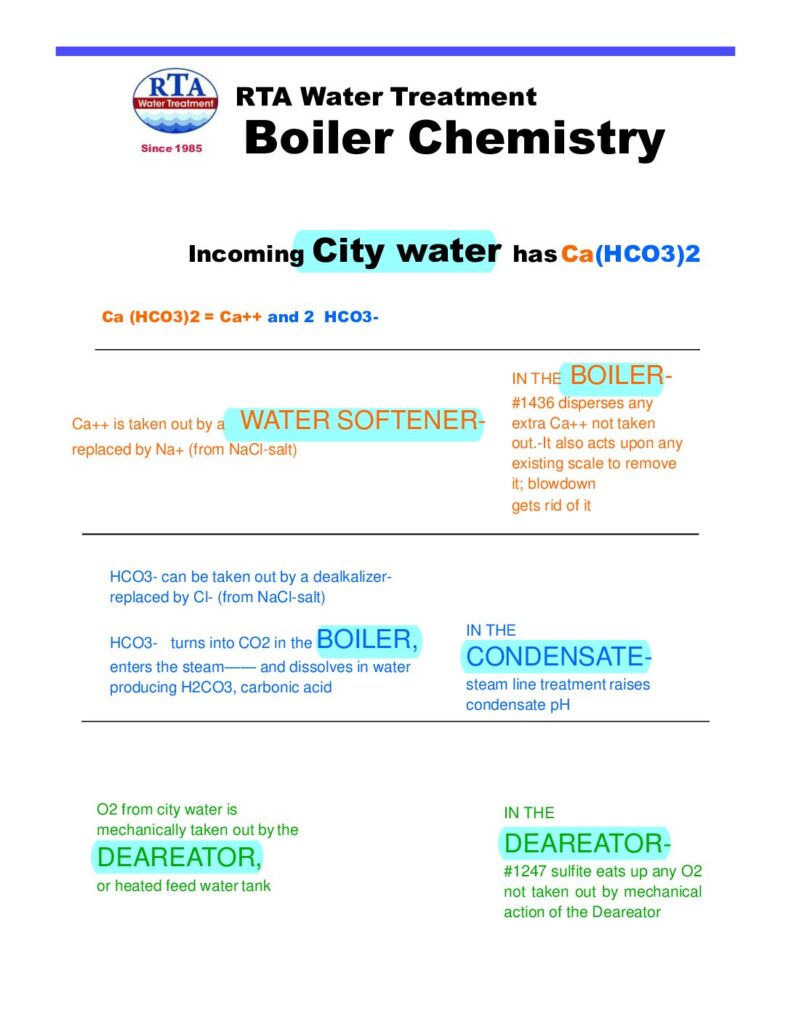

Additionally, with limited makeup to the system, less potential for deposit occurs. So for hot water boilers, with essentially very little or no makeup, softening of the make up is not necessary. Contact us for specific applications. See the “Boiler Chemistry” below Diagram. Note the effect of unsoftened water.

Large makeup and high pressure steam boilers

For larger makeup steam boilers, especially with higher pressures, softeners are necessary for the removal of calcium, magnesium, and other minerals. So they are especially critical in keeping boilers free from deposit. It is necessary to keep even very small amounts of calcium (and magnesium) hardness from getting into the boiler system to prevent deposits from occurring.

The diagram below shows why water softeners are necessary

1. Hard water enters from a city or well source,

2. The hard water is then softened, taking out the calcium and magnesium components of the hard water, together with some iron and other minerals.

3. Following the softeners, some systems include a dealkalizer. The dealkalizer takes out the HCO3- component in the water. Otherwise, when water is heated in the boiler, the HCO3- will produce CO2 (carbon dioxide). This carbon dioxide dissolves in the system condensate, producing corrosive low pH water, causing low pH corrosion.

Systems not having dealkalizers use steam line treatment to raise the pH in the condensate return lines so that corrosion does not occur. Limited amounts of steamline treatment (10% or so) are typically used even when a dealkalizer is present.

4. Deareators or heated feedwater tanks frequently replace an unheated feedwater tank. These eliminate O2 to a greater or lesser extent, depending on the type.